Fundamental principle

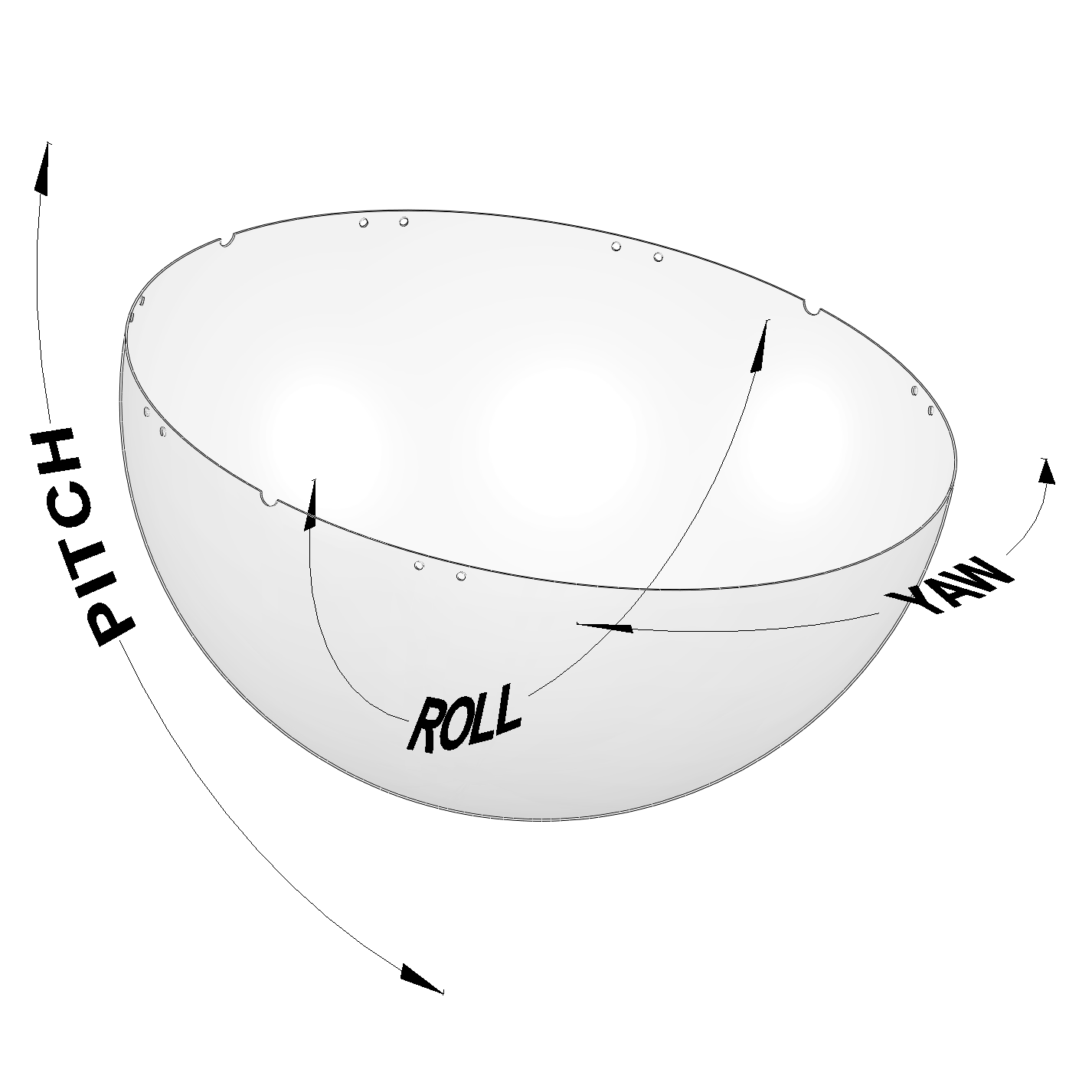

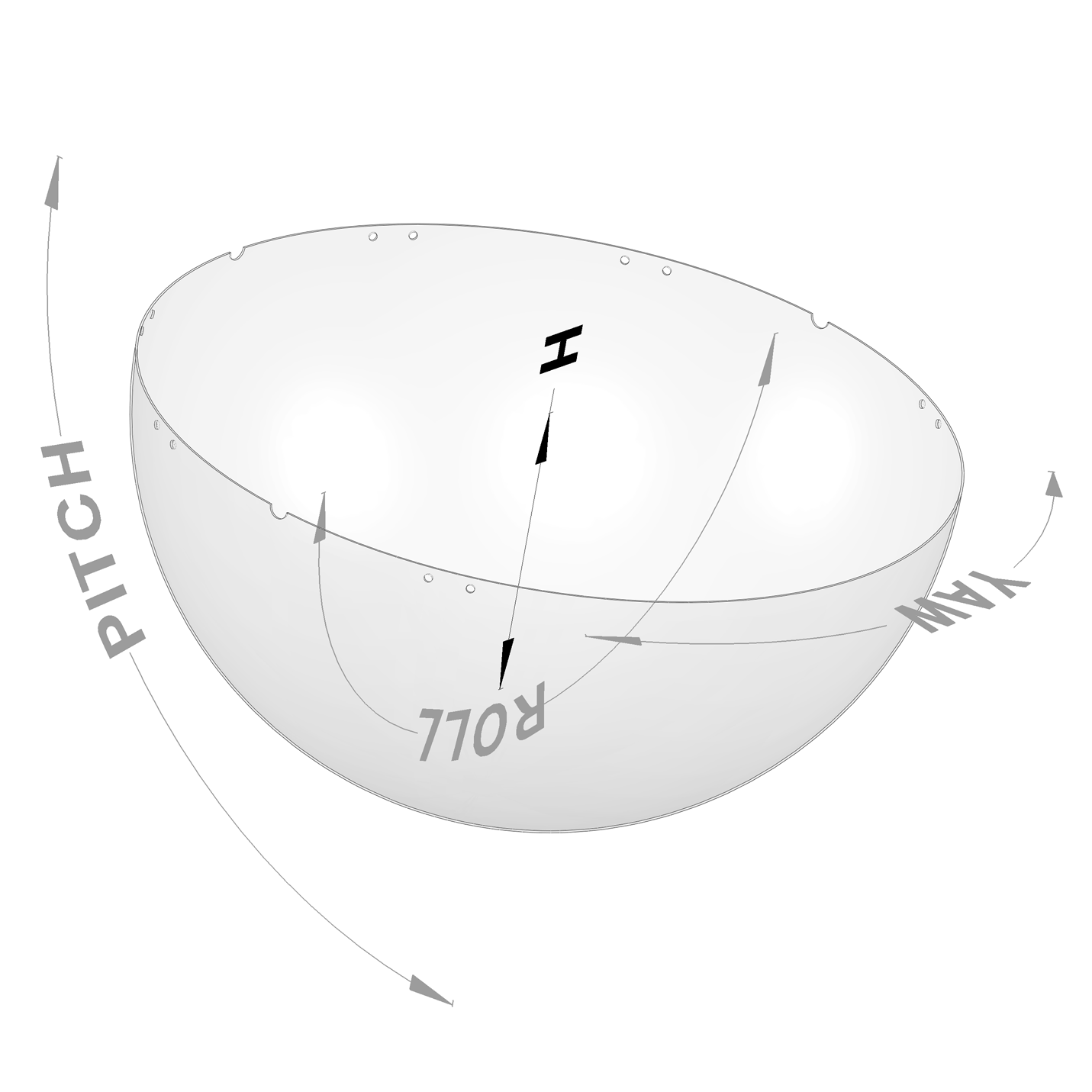

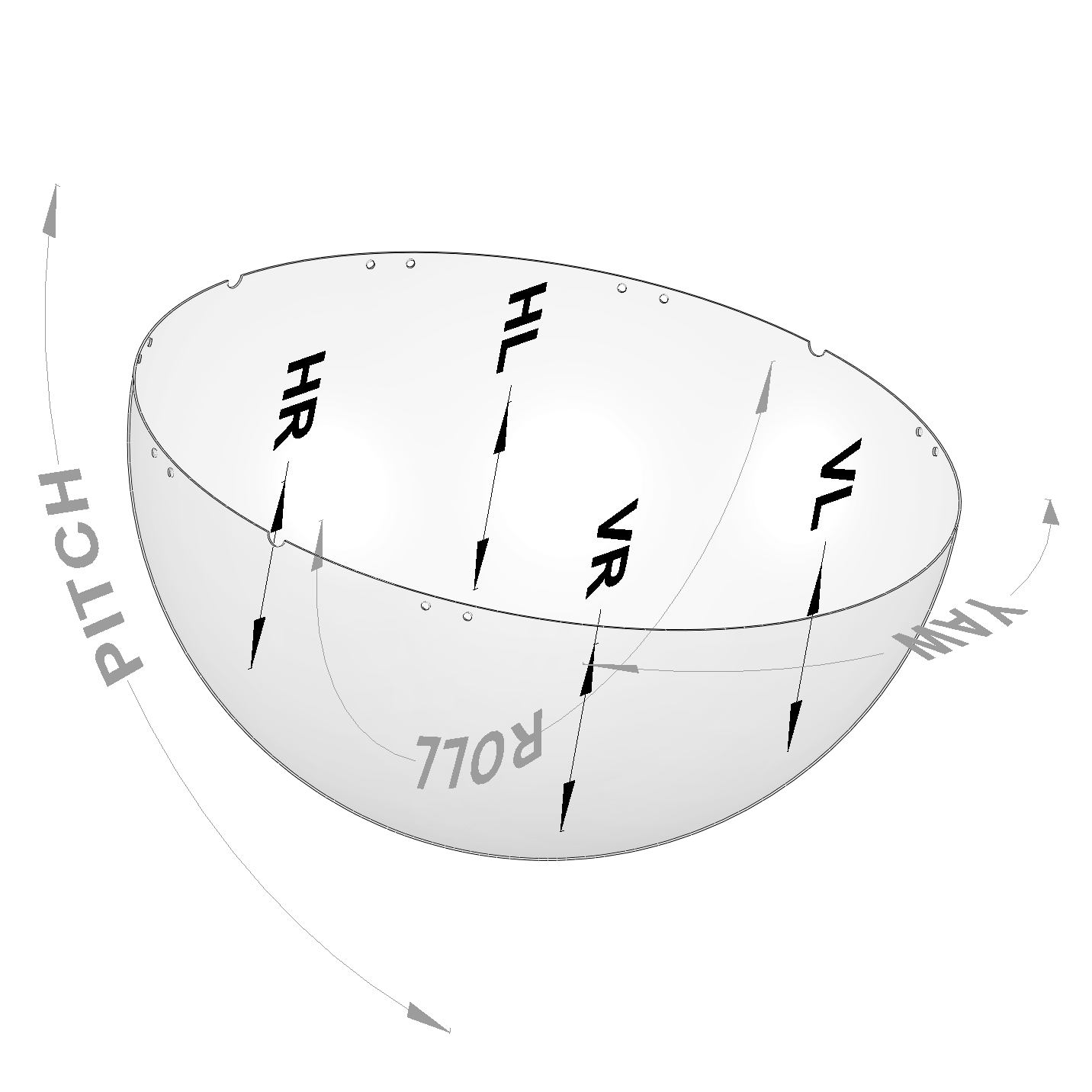

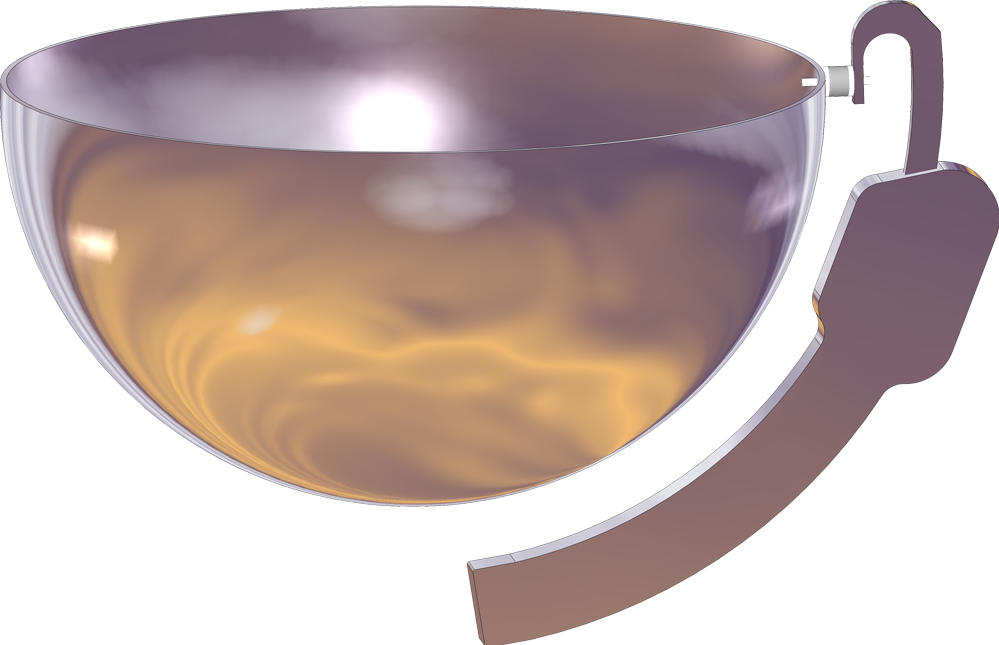

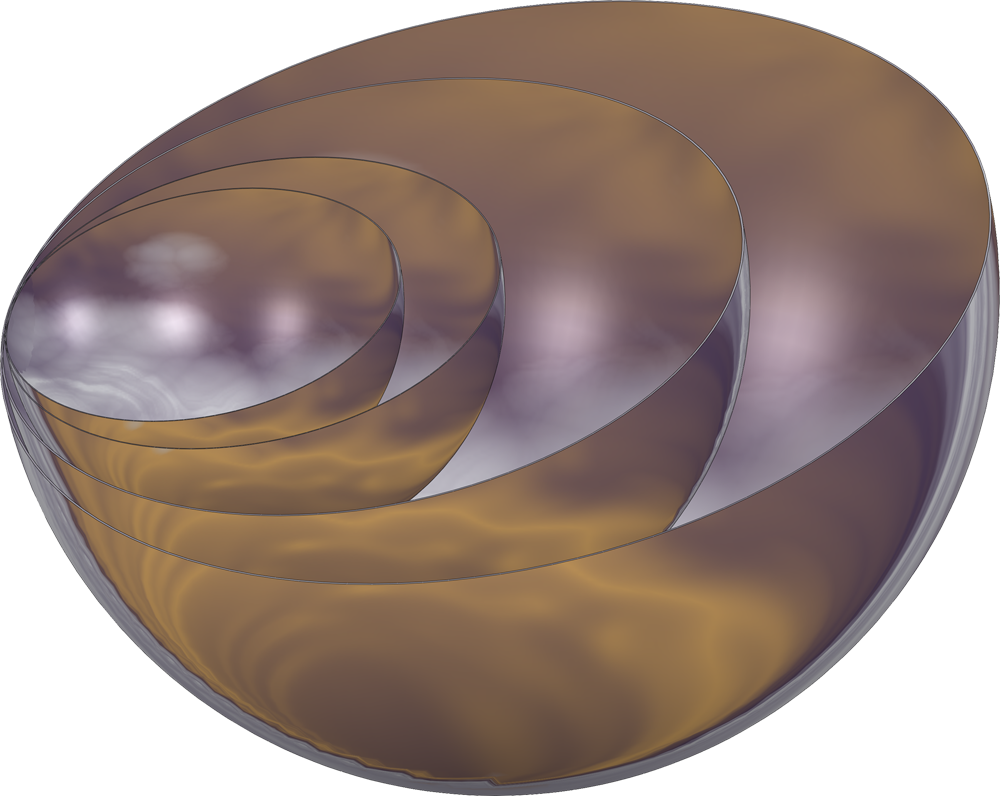

A hollow hemisphere is mounted free to move hemispherically. Three servo-motors enable motion about three axes (three DOFs): roll (±15°), pitch (±15°), and yaw (±15°). The respective applications are place in the hollow hemisphere along with the user.

Even large 'payloads' can be highly dynamically moved with low energy expenditure, because the centre of gravity lies at the sphere's midpoint in this construction. This principle of motion enables very gentle, but extremely effective, transfer physical forces of motion.